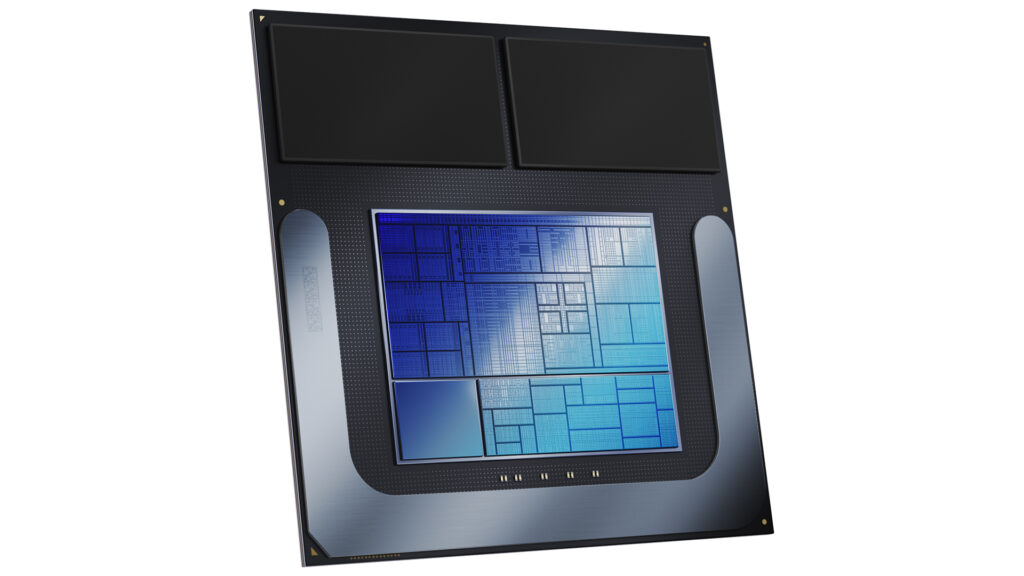

In a recent earnings call, Intel CEO Pat Gelsinger discussed the company’s latest mobile processor, Lunar Lake, describing it as a “one off” design that integrates memory directly into the microprocessor package. This innovative approach marks a significant departure from traditional laptop design, where memory modules are typically sourced from third-party manufacturers and either plugged into DRAM slots or soldered onto the motherboard.

During Intel’s third-quarter report, which revealed a staggering loss of $16.6 billion, Gelsinger elaborated on the implications of Lunar Lake’s design, stating that it was never meant to serve as Intel’s mainstream mobile chip. Initially conceived as a niche product focused on achieving high performance and exceptional battery life, Lunar Lake has since gained relevance due to the burgeoning demand for AI-driven personal computers. Gelsinger noted that the rise of AI PCs, along with the increasing importance of neural processing units (NPUs), has shifted Lunar Lake from a specialized solution to a more substantial player in Intel’s lineup.

However, this integrated memory design poses challenges for both consumers and Intel itself. Users seeking to upgrade their memory in the future will find that this integrated solution limits their options. Gelsinger expressed concerns regarding Intel’s ability to manage memory effectively, stating, “It’s not a good way to run the business,” highlighting the complexities involved in determining which processors require which memory capacities.

Looking ahead, Gelsinger confirmed that Lunar Lake would remain an isolated case. Future Intel processors, including Panther Lake and Nova Lake, will revert to a more traditional architecture, where memory is housed off-package. This approach aims to streamline manufacturing processes and restore Intel’s focus on its in-house production capabilities. Gelsinger emphasized the importance of Intel’s upcoming 18A manufacturing process, which is expected to play a pivotal role in transitioning the company through five distinct manufacturing nodes over four years.

With Panther Lake, slated for release in the latter half of 2025, Gelsinger noted that over 70 percent of its silicon area will be produced internally, reducing reliance on external foundries like TSMC, which currently manufactures Lunar Lake. This shift is crucial for improving profit margins and solidifying Intel’s position in the competitive semiconductor market.